Fabrication BOM Costing — Without Spreadsheets

Knowing what a fabrication job actually costs shouldn't require fragile spreadsheets or guesswork.

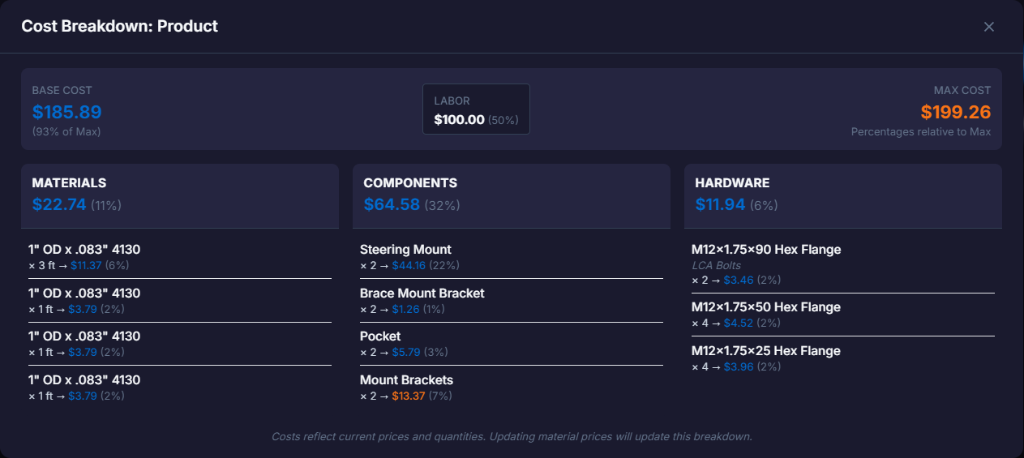

Arc Manager's BOM costing system is built to calculate real-world fabrication costs by tracking materials, hardware, and assemblies in a structured way — automatically.

Arc Manager is a Windows desktop application designed for fabrication and welding shops that want accurate costing without cloud dependencies or subscriptions.

Why BOM Costing Is Hard in Fabrication Shops

In many shops, BOM costing lives in Excel. Formulas reference other sheets, numbers are copied by hand, and small changes ripple unpredictably through the file.

As soon as a job includes multiple materials, hardware types, or sub-assemblies, spreadsheets become hard to trust. One missed update can quietly erase your margin.

Built-In Relationships Instead of Manual Formulas

Arc Manager approaches BOM costing differently.

Materials, hardware, and assemblies are entered as structured data — not cells and formulas. Each product's cost is calculated automatically based on the items it actually uses.

There's no need to maintain formulas, protect cells, or remember which sheet feeds which number. The relationships are handled by the system.

How BOM Costing Works in Arc Manager

Arc Manager calculates product costs by linking together:

- Raw materials

- Hardware

- Sub-assemblies

- Finished products

Each item is entered once and reused across your BOMs. This prevents duplicated data and keeps costs consistent across every product that uses those items.

When a material price changes, every related product updates automatically.

This keeps your costing consistent as your inventory and product catalog grow — all within a structured inventory system.

What Accurate BOM Costing Gives You

With structured BOM costing, you can:

- Quote jobs with confidence

- Catch unprofitable builds before production

- Understand where costs are actually coming from

- Scale your product catalog without breaking your numbers

- See exactly where each product's cost comes from, with a clear breakdown of materials, components, hardware, and labor

Instead of guessing, you're working from data you can trust.

BOM Costing in Arc Manager vs Excel

| Excel | Arc Manager | |

|---|---|---|

| BOM structure | Manual | Built-in |

| Formula maintenance | Required | None |

| Assembly relationships | Manual | Automatic |

| Risk of silent errors | High | Low |

| Designed for fabrication |

Who This BOM Costing System Is Built For

Arc Manager's BOM costing is built for fabrication and welding shops that:

- Build products from multiple components

- Track material and hardware costs

- Quote custom or semi-custom work

- Want reliable numbers without spreadsheet maintenance

If your Excel files feel fragile or stressful, this system replaces them with structure.

Desktop only

Guided demo • Shows core BOM workflow